Air Conditioning

Conditioned air is provided by:

- Left Pack

- Right Pack

- Ground source

The conditioned air is used to control temperature for:

- Flight deck

- Cabin

- Cargo compartments

- Equipment areas

The system provides automatic:

- Pack control

- Zone temperature control

- Cabin air re circulation

- Fault detection

- Overheat protection

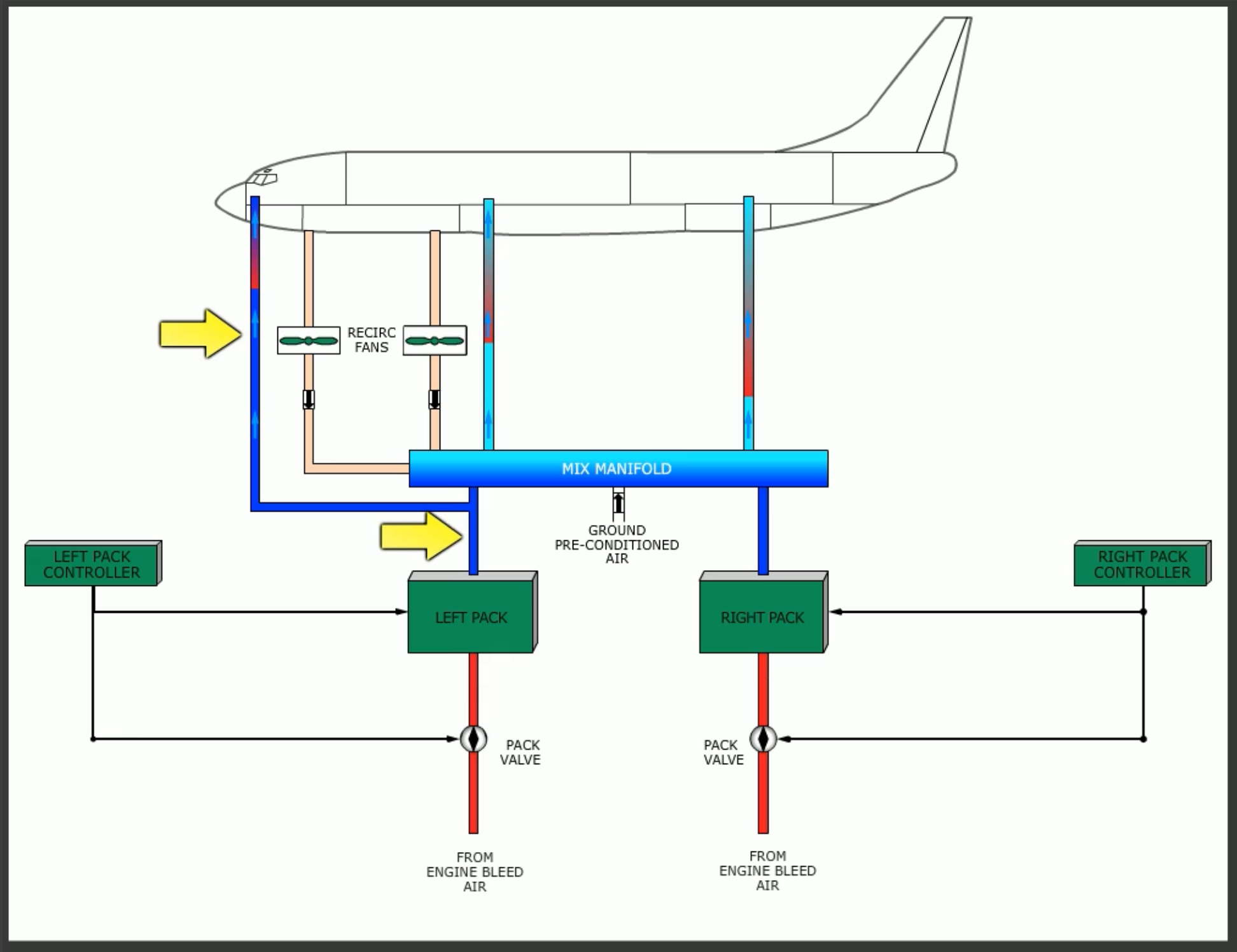

A portion of the AC system controls temperature by processing air (from engine bleeds, APU, or ground connection) via two identical packs. Bleed air enters the system from the pneumatic ducts through the pack valves. Additionally, pre-conditioned air can be pumped directly into the mix manifold from a ground air source.

Conditioned air from the left pack then flows to the flight deck, since it requires minimal air. The remaining air from the left pack is drawn into the mix manifold, where it is combined with air from the right pack and two recirc fans.

Note that the conditioned air going into the flight deck is not recirc air - it comes directly from the left conditioning pack.

The air is then distributed throughout the cabin via the left and right sidewall risers to an overhead distribution duct in the cabin. Air from the cabin and E&E compartment is drawn into the area around the forward cargo compartment by the recirc fans before passing through HEPA filters and then back into the mix manifold.

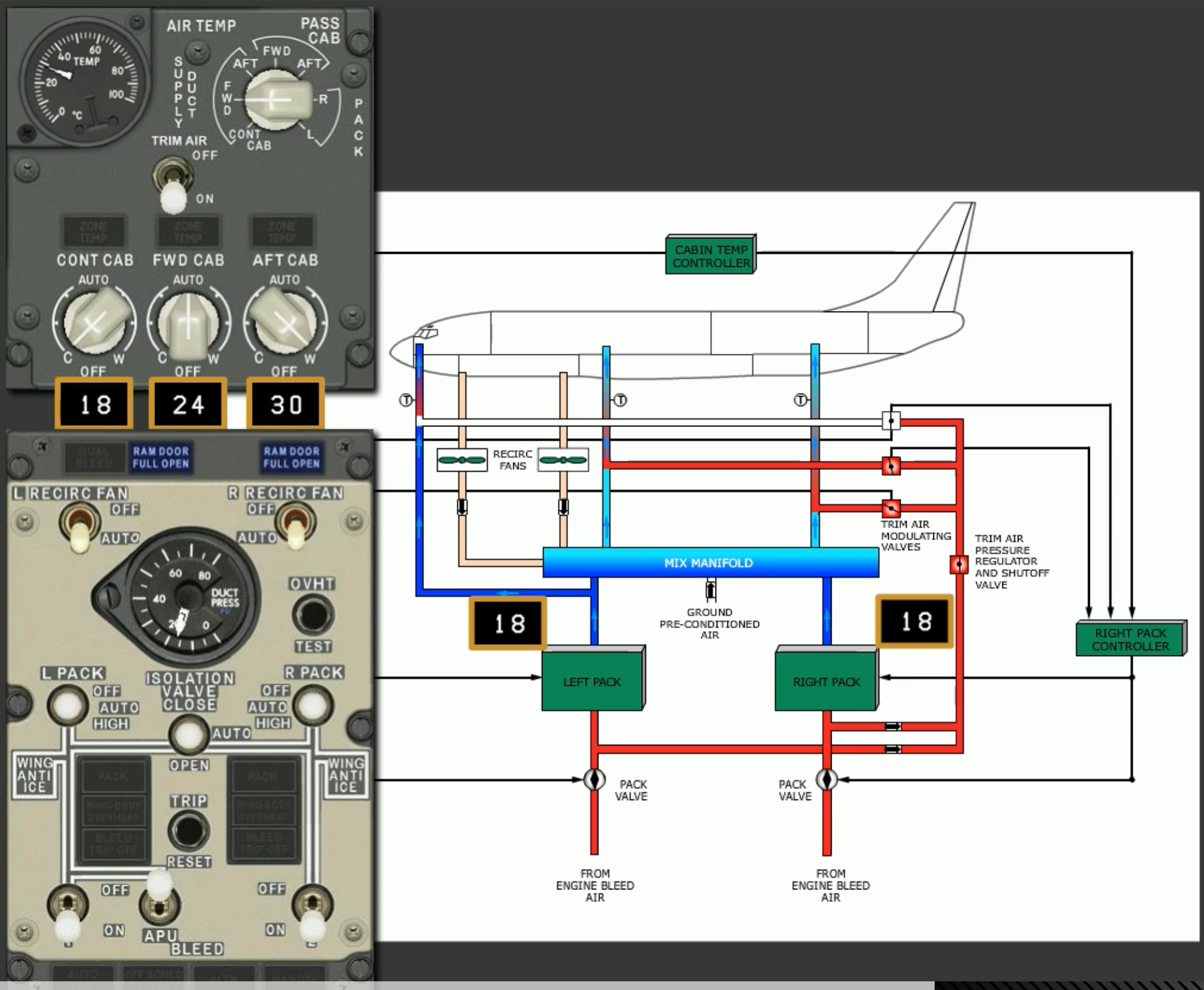

Furthermore, the aircraft is divided into three separate zones, with a TRIM AIR system used to fine tune air within each respective zone.

The system is monitored and control with the AC and Bleed Air panels. The packs are controlled by two identical pack controllers, each providing primary and secondary control of the various functions.

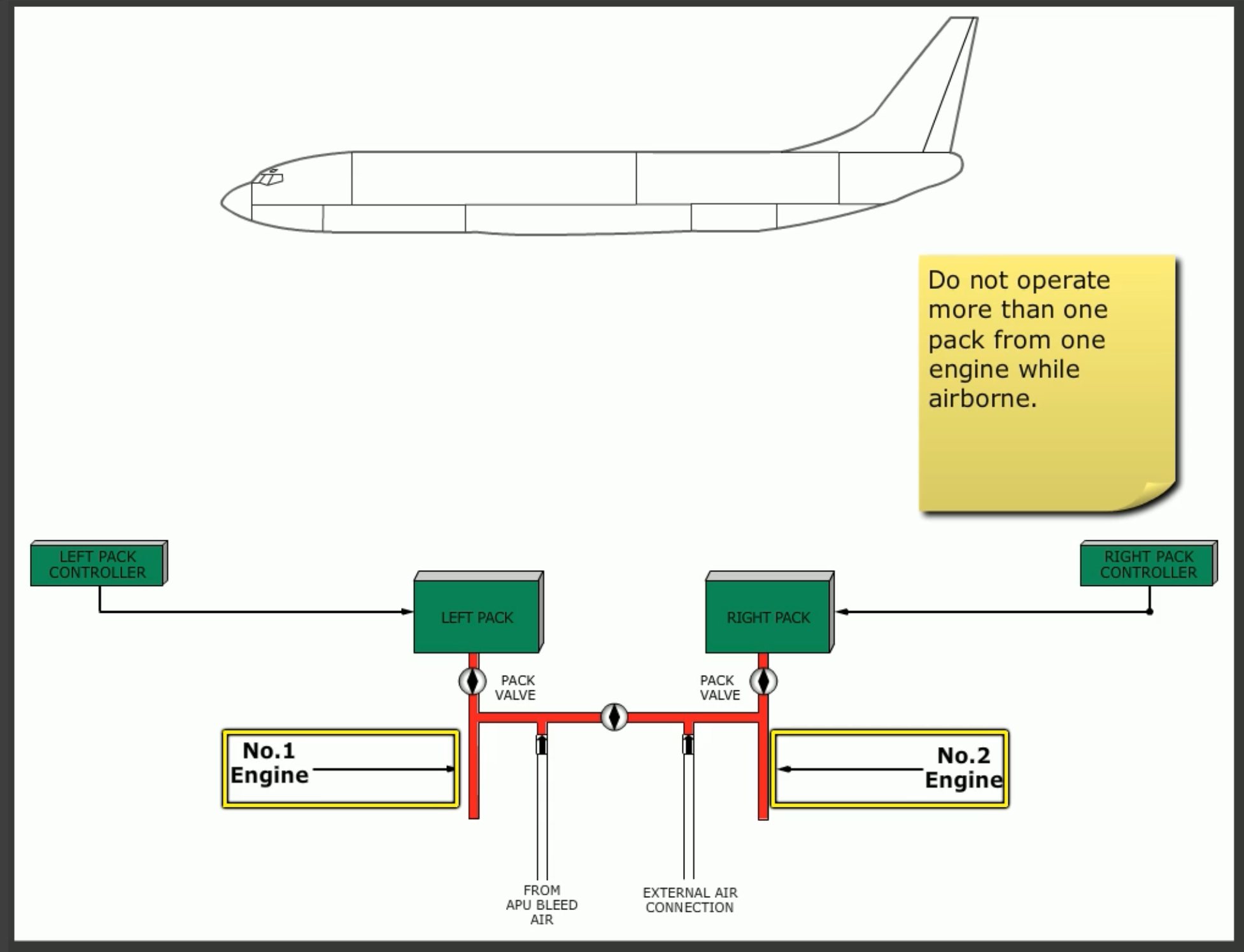

Normally, the left pack uses bleed air from engine #1 and the right pack uses bleed air from engine #2. Do not operate from than one pack from one engine while airborne. Should bleed air from an engine be unavailable, the APU can supply bleed air to one pack.

A single pack is capable of maintaining pressurisation and acceptable temperatures up to the max certified ceiling.

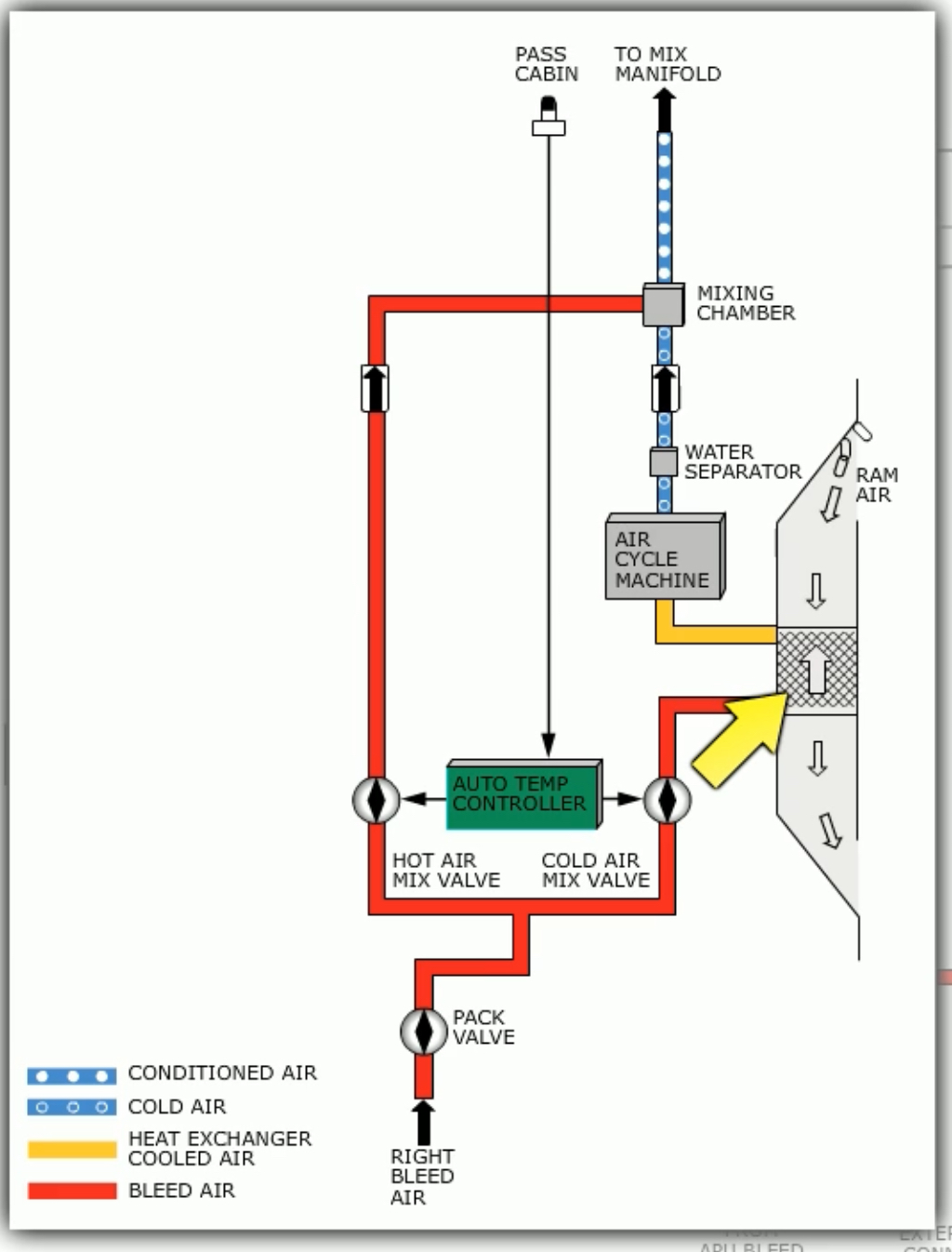

Before bleed air enters the pack, it passes through a flow control shutoff valve, known as the pack valve, which lets a controlled amount of air flow from the pneumatic system into the air conditioning packs. This valve is operated by each respective pack switch. Without airflow, the pack valves remain closed, as they are electrically actuated and pneumatically operated.

Once bleed air enters the pack, the stream is cooled by a primary heat exchanger using ram air.

The cooled air then enters the air cycle machine and is further cooled via a secondary heat exchanger. It then goes through a water separator before mixing with bypassed bleed air to obtain a a specific temperature. Finally, cooled air leaves the pack and flows into the mix manifold.

Ram air system

The ram air system provides cool ram air for the heat exchangers. The ram air doors are controlled automatically by the pack controllers.

On the ground or during slow flight with the flaps extended, the ram air inlet doors open to the full open position. This provides maximum cooling for the packs, and will be indicated by the blue RAM DOOR FULL OPEN lights.

During normal cruise flight the doors modulate between open and closed. There are no flight deck controls or indicators aside from the full open indications. To prevent slush and debris from entering the ram air system, deflector doors are installed forward of the inlets. These extend only on the ground, and are controlled by the PSEU.

Air Conditioning management and control

The pack valves control the airflow based on aircraft altitude and switch position. With the respective switches in the OFF position, the pack valves are closed and no air flows through the air conditioning pack.

With the PACK switches set to HIGH, the packs regulate to high flow. With both packs in AUTO, both packs operate in LOW flow mode; however, if only one pack is operating, the system switches to high flow in order to maintain adequate ventilation.

Automatic switching to high flow is inhibited while on the ground or in-flight with the flaps extended to ensure adequate engine power for single engine operation.

HIGH flow mode will also occur if both engine BLEED switches are off and the APU BLEED Air switch is on, regardless of flap position, air/ground status, or number of packs operating.

The RECIRC mans normally operate in the AUTO mode. They help reduce pack load by improving airflow throughout the cabin. However, if either or both packs are set to HIGH while in flight the system assumes that the flight crew wants additional air to be routed through the AC pack, which eliminates the need for the recirc fans to operate and thus:

If one pack switch is in HIGH, the left recirc fan shuts down. If both packs are in high, both recirc fans shutdown. However, on the ground the right recirc fan will always run regardless of pack switch position. The left fan will shutdown if both packs are on HIGH.

Temperature management

Air temperatures can be seen via the AIR TEMP indicator and selector on the overhead panel, although only one position at a time is available:

- The Supply Duct selectors indicate the temperature at the ducts entering the cabin distribution system within the selected zone.

- The Left and Right back selectors indicate the temperature just downstream of the packs themselves.

- The PASS CAB switches can be indicate the temperature in different zones of the cabin.

The ZONE TEMP lights on the overhead indicate specific overheat or failure of one of the three zone controllers:

- CONT CAB (Control Cabin, or Flight Deck)

- FWD CAB

- AFT CAB

The CONT CAB ZONE TEMP light indicates a duct temperature overheat or failure of the flight deck primary and standby temperature controls, while the FWD CAB and AFT CAB lights only indicate duct temp overheats.

The desired zone temperature is adjusted by individual temp controls with a range of approx. 18 - 30 degrees C.

TRIM AIR and distribution

Additionally, the aircraft is equipped with a TRIM AIR system, which, when enabled, opens the trim air PRSOV allowing the operation of the individual trim air valves. This system works by allowing the packs to produce an air temperature to satisfy the zone that requires the most cooling. the trim valves then modulate specific zone temperature by adding proper hot trim air directly from the bleed air system into the cabin supply ducts.

During single pack operation with the TRIM AIR system off, the pack attempts to produce an air temperature that is the average of all three selected zones.

On the other hand, if TRIM AIR is off with both packs operational, the system goes into “split pack mode”, causing each pack to operate independently. The left pack will produce a temperature to satisfy the flight deck, while the right pack will produce an average temperature to satisfy the aft and fwd zones.

If any temperature zone control is selected OFF, the TRIM AIR system simply ignores that particular zone and closes the relevant valve. If all controls are set to off, the aircraft is in Fixed Cabin Temperature mode: the left pack will produce air at 24 degrees, while the right pack will produce air at 18 degrees.

Any failure of the TRIM AIR system will command both packs to operate independently. Should TRIM AIR fail to the CONT CAB controller, the left pack produces air to satisfy flight deck, while the right pack will satisfy the cabin zone that requires most cooling. Failures to either cabin zone TRIM AIR systems will force the right pack to satisfy the average temperature for the FWD and AFT zones.

The flight deck air is routed into several risers on the ceiling, floor, and foot level outlets. On the floor there are air diffuses that operate as long as the manifold is pressurised. Additionally, there is a valve behind the each of the rudder pedals that provides warm air for defogging the windshields.

Electronic component cooling

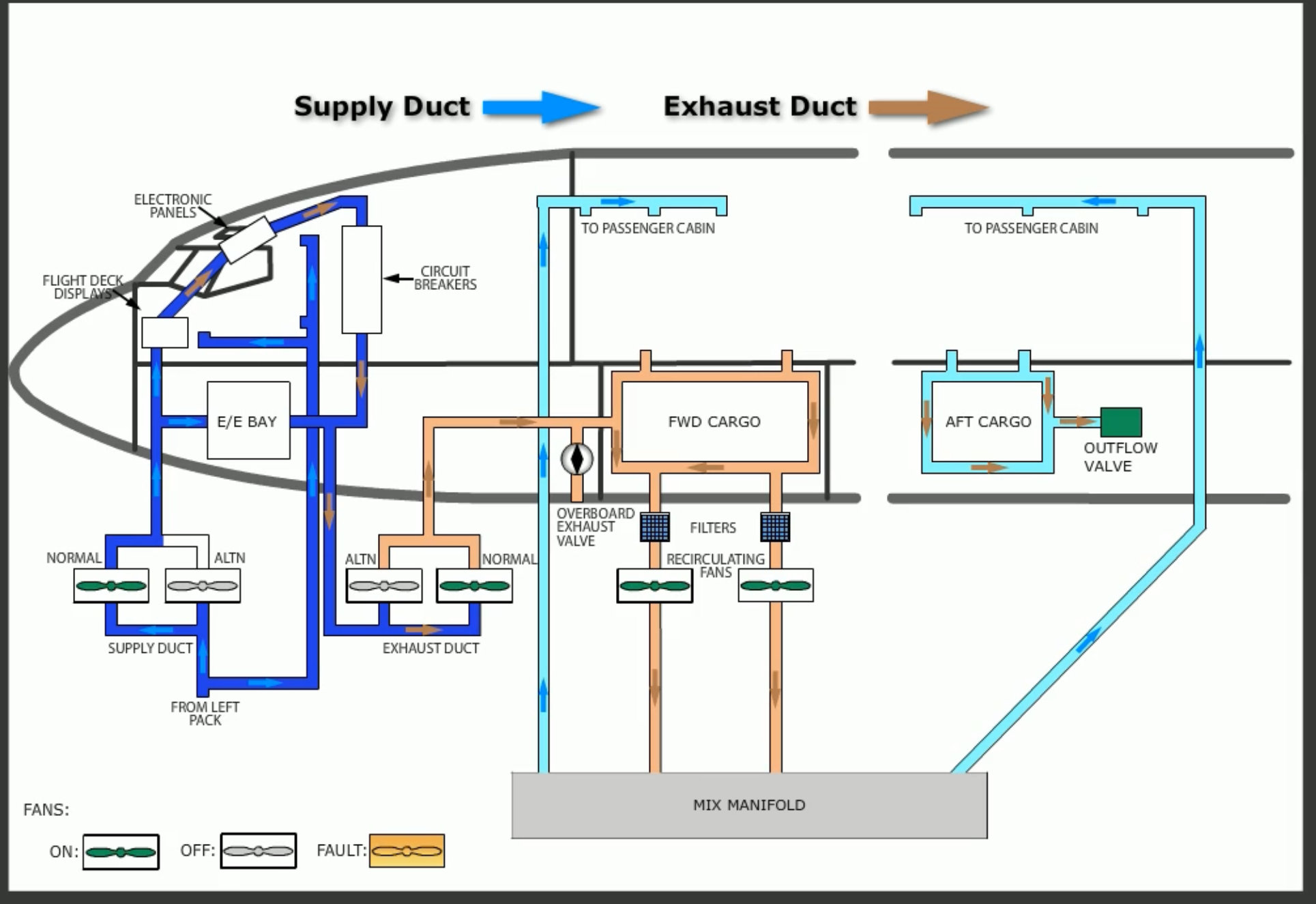

The air conditioning system is also used to cool electronic components in the flight deck and the E&E compartment.

The system consists of a supply duct and an exhaust duct, each of which has two fans: normal and alternate.

The supply duct pushes cold air over the:

- Display units

- FMC displays

- Center aisle stand

- Equipment racks in E&E compartment

The exhaust duct draws warmed air from all of the above and the circuit breaker panel into the FWD cargo compartment and into the recirc fan ducts.

The aircraft is equipped with flow detect sensors. When there is not sufficient cooling airflow the OFF light, master caution, and overhead lights illuminate. The OFF light will illuminate the appropriate OFF light for either SUPPLY or EXHAUST. Switching to the ALTN fan mode will extinguish the light within 5 seconds, once proper airflow is restored.

Cargo compartments

The FWD Cargo compartment is warmed by recirc air from the passenger compartment as well as E&E exhaust air when the overboard exhaust valve is closed.

The AFT Cargo compartment is warmed by recirc air from the cargo compartment, and is then ducted overboard through the outflow valve.

Pack failures

The PACK light illuminates to indicate a pack trip off due to an overheat or a failure of both primary and standby pack controls. When a pack detects an overheat condition, the pack valve will close and associated MASTER CAUTION, PACK, and AIR COND lights will illuminate.

Should the fault be corrected, the TRIP RESET switch resets the PACK light in an overheat condition. The related pack opens and the light extinguishes. However, if the fault condition is NOT corrected and the PACK light remains illuminated then the fault is due to a dual controller failure.

In a dual controller failure situation the pack operates in an uncontrolled state and fails open. The valve will not closed until it is commanded off with the pack switch. The AIR COND light will illuminate during Master Caution recall to indicate failure of either primary or standby pack control.

Which pack provides air for the flight deck?::Left pack.

How is air from the left and right pack combined?::Via the mix manifold and the aid of two recirc fans. Can you operate both packs with a single engine?::No, but the operation can be aided by the APU. How is bleed air cooled before entering the mix manifold?::First by ram air, then an air cycle machine. Air then flows into a water separator before being mixed with bypass air, then finally entering the mix manifold. When is high flow not available?::On the ground or in flight with flaps extended.

When will the packs auto switch to HIGH flow?::When only one pack is operating. It will also occur if both engine BLEED switches are off and the APU BLEED Air switch is on, regardless of flap position, air/ground status, or number of packs operating.

What do the pack valves do?::They function as both flow control and shutoff valves.

How are the pack valves actuated and operated?::Electrically actuated and pneumatically operated.

When does the PACK light illuminate?::When there is a pack trip off due to overheat or a failure of both primary and standby pack controls.

Will a pack close due to dual controller failures?::No, the pack will fail open. It will not close until the pack switch commands an off position.

When are the ram air inlet doors fully open?::On the ground or during slow flight with flaps extended. This will be confirmed by the RAM DOOR FULL OPEN lights. Where does air for the flight deck and the cabin come from?::Air for the flight deck comes directly from left pack, while cabin air comes from the mix manifold - where recirc and pack air is mixed.

When do the recirc fans shut down in AUTO mode?::Whenever either or both packs are set to HIGH in flight.

How do you AUTO shutdown both recirc fans in flight?::By switching both packs to HIGH.

What does the CONT CAB ZONE TEMP light indicate?::Failure of primary and standby temperature control or duct temp overheat.

What is Fixed Cabin Temperature mode?::A situation that occurs when all temp control switches are set to off. The left pack produces air at 24 degrees, while the right pack produces air at 18 degrees. How is the aft cargo compartment heated?::Via recirc air from the cabin compartment.

Where does the mix manifold receive air from?::Left pack, right pack, recirc fans.

When will a pack automatically go to high flow?::When operating one pack from APU, with both engine BLEED switches OFF or with one pack operating in flight with flaps retracted.

FWD SUPPLE DUCT temperature indicates temperature from ___ ::The duct temperature leading to the forward passenger zone.

Cargo heat is controlled from the flight deck.::False.

The purpose of the recirculation fans is::To reduce pack demand for bleed air.

With a ZONE TEMP over the CONT CAB::The left pack produces what is selected on the CONT CAB selector, and the right pack produces the coldest between FWD and AFT zones.

The equipment cooling systems contains ___ fans.::4 fans, 2 supply and 2 exhaust.